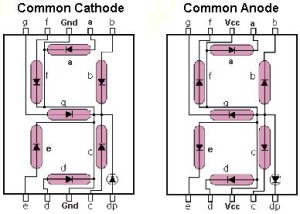

Recently the STEMLAND name board made using SSD had got dim and the 7th std students took it as a project to fix it. They de-soldered the dim SSD’s and Replaced it with new ones.

Barani got interested in the SSD’s and started powering them up using the Arduino, he manged to code the Arduino to print all the numbers 0-9 using two SSD’s

Then to take a step further he started his quest to build a clock. He had added a counter to light the corresponding diodes in the SSD along with Sanjeev, this was done using a 9V battery.

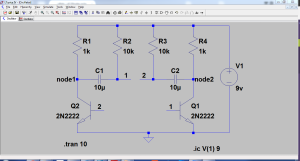

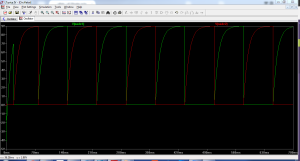

As I already mentioned in my blog that Deepanam children built an oscillator. Bharani used the output of the oscillator as an input and made the clock count from 0 to 9.

Bharani making the clock count by removing and inserting the input each time.

Giving input from the oscillator built by Pravina (Deepanam kid).

Arun and Sundar